The usual strong back, a robust pair of hands, and committed work ethic used to be the most desirable qualities of a new hire in manufacturing. While these attributes are important, there has been a transition from assembly-line manufacturing to technology-based manufacturing, thus impacting the way a CNC Machine Shop

Robots on the Rise — Rapid Advances in Automation

It is common knowledge that companies and educational institutions are doing what it takes to keep up with the ever-evolving field of automation. Robots and robotics impacts work and workplaces in new ways, every day.

Automation Changes Every Thing

Automation is changing how we live, how we work, and how we spend our

How to Choose the Right Tools for the Job: Examples of CNC Machine Tasks

Just because the world of manufacturing has changed doesn’t mean that people need to stray from the basics. It is just as important to choose the right tools for the job today as it was hundreds of years ago. In actuality, as technology has advanced, there are more tools at

The Evolution of Manufacturing

It’s no secret that technological advances have changed every sector of the economy and this is just as true in the world of manufacturing as it is in any other industry. Those who have experience working in the manufacturing field know how the field has changed over the past few

What is CNC Machining?

It’s no secret that the work done within a machine shop has changed significantly over the past few years. The world of manufacturing used to be dominated by assembly lines where workers would perform the same tasks over and over again to rapidly produce high-quality products. As the technology in

U.S. Manufacturing Myths and Misconceptions

It’s impossible to pinpoint when we collectively became Debbie Downers regarding U.S. manufacturing. People appear to equate the rise of Chinese manufacturing with the decline of U.S. manufacturing, although there is no truth to it. In fact, there is no truth to many of the myths and misconceptions about Manufacturing.

How to Stay Safe in a Manufacturing Facility

Safety in the workplace is important no matter what line of work someone is in, but in the cnc manufacturing industry, it’s one of the most important factors. Manufacturing, with its heavy-duty equipment, long hours, and endlessly tight deadlines supporting other industries around the world, can be extremely dangerous if

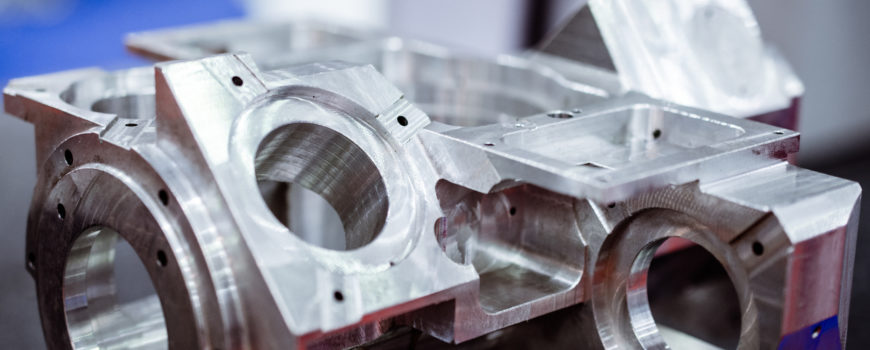

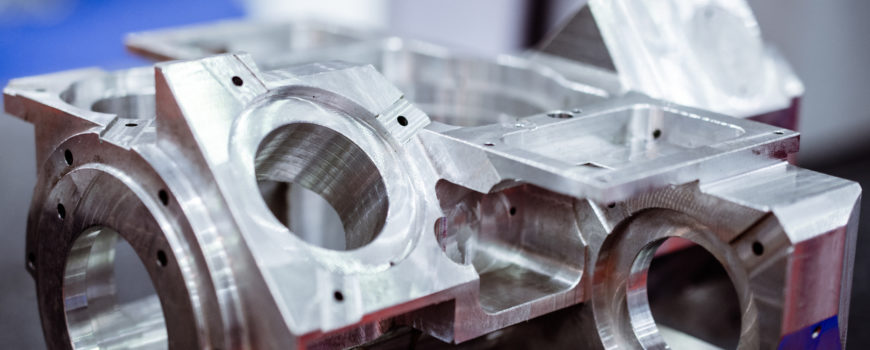

Achieving Maximum Efficiency in Machining Tight Tolerance Parts

The best practices for precision manufacturing come from using computer numerical controlled (CNC) machining. CNC manufacturing uses high-speed, robot-driven machines and specialized cutting equipment in a custom machine shop. A machine shop for CNC manufacturing will have vertical and horizontal milling machines and lathes.

This CNC process can make custom machined

What you can Expect from a Career in CNC Machining

At some point in his or her life, everyone has to make a decision as to what they want to be when they grow up. It is not uncommon to continue to ask oneself that question into adulthood. If you’ve ever wondered what it would be like to be a CNC

Energy Efficiency – The Key to Success in Manufacturing

In today’s world there is a great deal of focus on sustainability and energy efficiency. It seems everything, from cars to buildings, is measured by its carbon footprint, or environmental impact. Other countries, such as the United Kingdom, have strict energy regulations in place for manufacturing industries and for machine

Challenges Manufacturers will face and how to overcome them in 2019

Manufacturers are constantly faced with a variety of challenges and staying competitive and profitable requires the ability to identify issues and enact effective resolutions that can adequately provide a remedy. One of the biggest challenges manufacturers will face in 2019 is creating new markets for custom manufacturing. Perhaps a company

Improving your Machine Shop

A machine shop can be compared to the parts that are manufactured on a daily basis, with many moving parts, all of which needs to work together in synchronized processes to achieve the maximum efficiency in a machine shop. It’s a delicate balance to keep the machines running at tiptop

Enhancing Workplace Safety with 5S

5S is lean Six Sigma approach designed to reduce waste and maximize productivity by keeping an orderly workplace and achieving consistent results that can be checked via visual cues. Implementation organizes the workplace within its existing framework, and this is the first step toward a lean Six Sigma effort. However, in

10 Amazing Benefits of One-Stop Machine Shop Employment

Have you ever thought about pursuing a career in manufacturing? Whether you realize it or not, there are lots of hidden benefits for working in a CNC Shop. Like buried treasure in a forgotten hill, machinists and manufacturers have lots of career perks that most people overlook. Let’s review the

Benefits of Working with an Original Equipment Manufacturer (OEM)

Original equipment manufacturers (OEM) parts make a difference and that variation is amplified in precision machining. The benefits of OEM parts are important and will make a difference in any industry, some are just more pronounced than others. To make this case obvious, we should begin by looking at the