The usual strong back, a robust pair of hands, and committed work ethic used to be the most desirable qualities of a new hire in manufacturing. While these attributes are important, there has been a transition from assembly-line manufacturing to technology-based manufacturing, thus impacting the way a CNC Machine Shop hires prospective talent. Today’s workers require a wider scope of skills for success including,

One: Ability to be Cross-Trained

Whether you are applying for a position as a CNC machinist in a CNC machine shop, line worker, quality engineer or other Denver manufacturing function, you must be flexible enough to cross-train in other areas. There are so many job tasks required to keep manufacturing running smoothly so those employees who have been cross-trained are highly valuable to the company.

Life happens – employees go on vacation, get sick, or don’t show up for work. If you can be cross-trained in a variety of functions, supervisors can add you to fill in the gaps. Also, those who showcase the ability to be cross-trained in a variety of functions make excellent supervisors and trainers in the future.

Two: Ambition

Although you may start in an entry-level position as a CNC machine shop Denver-based employee, that does not mean you cannot rise through the ranks. Companies want employees who are driven and motivated, who will go beyond the normal scope of their position when requested.

Ambitious employees are hard-working individuals who are regularly searching for ways to become more efficient and effective. These types of workers always have a higher chance of being considered for more challenging jobs when the opportunity presents itself.

Alongside ambition, hiring managers search for integrity and honesty during the interviewing process. For instance, when recognized for an achievement, the ambitious worker commends their colleagues who helped them succeed. Appreciating co-workers shows you are a team player who may be right for a leadership position in the future.

Three: Attention to Detail

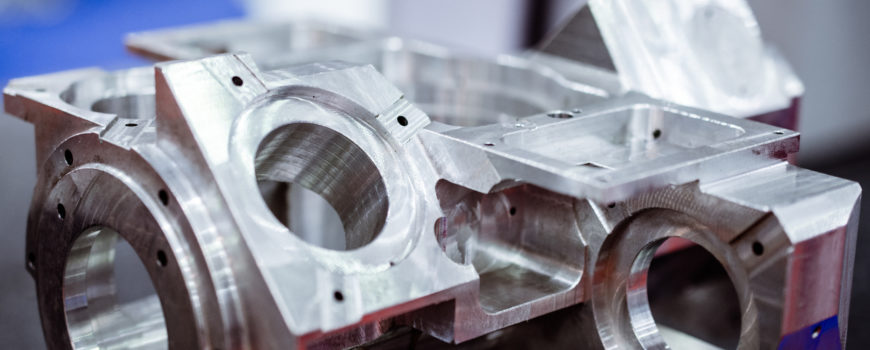

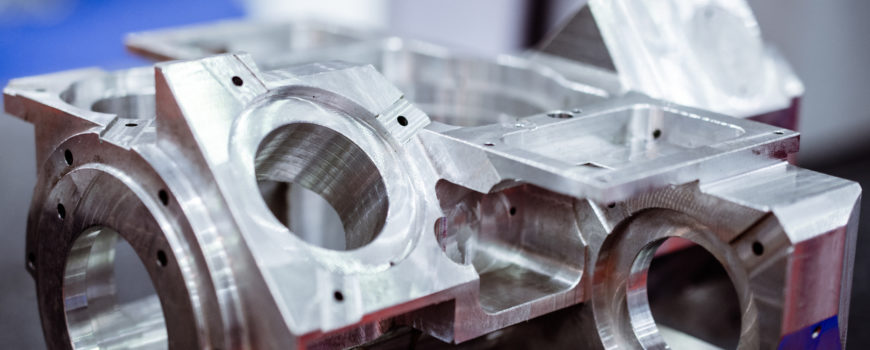

Whether you are working for an original equipment manufacturer (OEM), in a custom machine shop or some other type of production, attention to detail is of the utmost importance. There are few positions where attention to detail is not important.

In manufacturing and when designing custom machined parts in a CNC machine shop, speed and precision are critical. Most manufacturing plants require the operation or interaction with heavy machinery so a lack of attention to detail can result in danger for you and your colleagues.

Four: Critical Thinking

The modern manufacturing employee must be able to think fast and quickly troubleshoot even the smallest of issues before they become major problems. Supervisors cannot individually solve every little issue throughout the day. Therefore, hiring managers seek those who can make accurate, rational, and quick decisions when unforeseen circumstances arise.

Five: Dependability

Although this is a required trait for any position, it is especially true in precision manufacturing and other areas of production. Manufacturing plants are large spaces with many employees so supervisors must be able to account for their staff with little oversight. Employees who excel with little supervisor involvement will create a successful career.

In addition to being dependable daily, arriving on time and ready to work is related. The best rule of thumb is to target arriving 15-minutes early so that you are not rushing to your station or work area. Rushing can also lead to a safety issue in an industrial environment.

Six: Enthusiasm

Enthusiasm runs together with the ability to be cross-trained and ambition but is slightly different. Manufacturers want candidates who are passionate about the job with which they are seeking. The passion and enthusiasm for a position should be glaringly obvious during the interview process.

Those who love their job tend to stay with companies longer than those who are only seeking a paycheck. Enthusiasm and passion are excellent traits for new employees to possess because they become useful to the company when leadership opportunities arise in the future. Enthusiasm from younger employees is especially key as management can help mold them into the perfect employee for that organization.

Seven: Interest in Technology

All US manufacturers love those who are genuinely interested in technology since it is a regularly evolving field that changes manufacturing operations. As soon as five years ago, the smartphone revolutionized manufacturing, and today, it is drones. In a few more years, production could be driven by artificial intelligence.

By showing a learning interest in technology, you are sending a message that you want to be part of their organization for the long-haul. When submitting your resume, make sure to highlight this desire to learn and succeed.

Eight: Positive Attitude

Possessing a positive attitude is essential for all positions. However, in manufacturing, there are many difficult tasks and positions that need to be fulfilled to ensure smooth and efficient manufacturing. Therefore, when asked to do an unfavorable task, those employees who do it with a smile on their face will always shine above those who complain and grumble.

Having a positive attitude during an interview process speaks volumes about the character of the candidate. For instance, all employees have dealt with difficult work situations in the past and when this question arises, those candidates who positively explain the problem and their solution, are a much larger asset to the organization.

Nine: Strong Communication

Communication is a top skill to possess in all industries but is especially essential for CNC manufacturing. If you can successfully communicate with your co-workers and superiors to achieve greater goals for the company, this shows you are a team player who is committed to the success of the organization. This makes you a highly valuable and well-respected employee.

Ten: Team Player

All types of manufacturing cannot be successful unless all employees work as a team. From assembly line production to technology-based manufacturing, all employees must do their part in the process to ensure the next worker can do theirs. Even at the management level, all departments must work together to meet the goals of the organization.

While all these skills are critical to being successful in manufacturing, it is rare to find an employee who possesses them all. However, through continuous personal development of manufacturing employees, supervisors, and upper management, skills can be refined, and new traits can be learned to better foster and improve these traits.

If you feel you embody these traits, contact Tag Team Manufacturing and apply for a position in their Colorado CNC Machine Shop.