It’s no secret that technological advances have changed every sector of the economy and this is just as true in the world of manufacturing as it is in any other industry. Those who have experience working in the manufacturing field know how the field has changed over the past few decades. Manufacturing has come a long way from the first assembly line and, now, people might think that custom machined parts, advanced machinery and robots are changing the field permanently. In order for a business to rise to meet these changes, they also need to understand the course of manufacturing evolution over the past few decades. How has manufacturing evolved from its roots to the present?

The Early Days of the Manufacturing Industry

Custom machined parts haven’t always been around as manufacturing has changed significantly over the past several decades. Many people look at the advent of the Industrial Revolution as the starting place of manufacturing. This was the first time that interlocking parts were used to create high-output facilities that could produce identical parts quickly. Despite the use of machines to produce parts, the human hand still played a critical role.

Unfortunately, one of the major problems with manufacturing during this era was safety. People were intimately connected to large machines with dangerous moving parts. One mistake could place someone in the hospital, rendering them unable to work or provide for their family. Furthermore, there were health concerns associated with many of these facilities. Because many of these factories were coal-powered and workers were kept in close quarters, illness was common. If someone got sick, that illness could spread through the entire building in a short period of time.

Finally, a huge safety issue was fires. There are numerous stories of the early days of manufacturing of large conflagrations that rapidly engulfed entire buildings. One example is the Triangle Shirtwaist factory fire that took place in New York City in the early 1900s. It is still regarded as the deadliest manufacturing disaster in the history of the United States, as it resulted in the deaths of nearly 150 people. Fortunately, technology improved and changes were made that placed worker safety at the top of the priority list.

The Assembly Line Changes Manufacturing

As technology progressed, thinking changed. The leaders of the world of manufacturing looked for ways to increase output to meet the rising demands of consumers. With this, the assembly line was developed. Many people credit the first use of the assembly line to Henry Ford, which he used to build the first affordable automobile, the Model T. In the assembly line, workers are trained to perform the same task over and over again. Because they are performing the same task, they become experts at this task, allowing them to perform this task faster than anybody else. By combining many people who are experts at their singular task, production and output increase. The assembly line completely changed how manufacturing was performed.

Computers Change the Manufacturing Industry

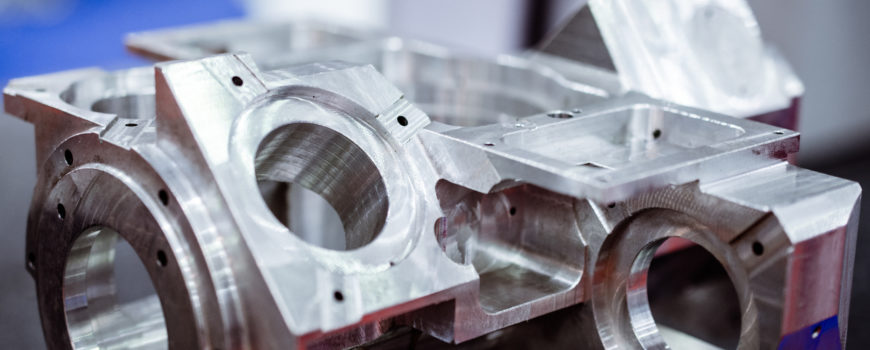

As the 20th century rolled on, computers started to play a role in the manufacturing industry and changed the fundamentals. With the advent of computers, workers became able to give the computer commands, allowing more precise tasks to be performed. The early days of computer manufacturing involved punch cards that were used to deliver commands. Then, the computer would spit out answers or perform tasks based on those punch cards. Computers and machines are able to perform tasks more quickly and more accurately than human hands. By removing humans from the front lines, factories became safer and humans were largely able to work behind operational controls.

Automation as the Next Step

Technology continued to progress and no area was left untouched. This includes manufacturing and its custom machined parts. As computers became both smarter and smaller, automation developed. Automation is the ability of machines to perform the same task over and over again without requiring additional input from the human hand. Automation became common in the average precision machine shop, leading to significantly increased production capabilities. Machines that are automated do not get tired and, thus, led to the development of 24-hour per day production. Furthermore, these automation robots are also more accurate than the human hand. The manufacturing industry exploded as production and accuracy both increased. Instead of humans turning the screws and tightening the bolts, robots were able to do this. Now, the people became responsible for delivering commands to the machines, changing their jobs when necessary.

Manufacturing in the Contemporary World

Over the past few years, there have been several additional major changes in the world of manufacturing. Some of the examples include:

Workers are More Highly Skilled: Because the manufacturing industry is producing more complex items than ever before, the workers must also be more highly skilled. Those who work in the manufacturing industry often have advanced training in areas such as computer science and robotics.

Higher-Value Goods are Produced: Due to the advent of technology, the manufacturing industry is also producing more high-value goods than ever before. This includes advanced vehicles, accessories for computers, and other connected devices.

The Job of the Human Hand Has Changed: The days of workers getting their hands dirty in a steel mill or coal mine are now relegated to the pages of history. Today’s manufacturing employees are working on a squeaky clean factory floor delivering commands to precision computers that perform a majority of the step-by-step tasks. This is both faster and safer than the early days of manufacturing.

Manufacturing in the Global World: Finally, the world of manufacturing is now a global place. Many of the goods produced in factories today are exported to other countries. The original equipment manufacturer (OEM) is distributing products around the world. The growth of logistics has allowed this to happen. The world is more connected than ever before and Denver Manufacturing is at the heart of these custom machined parts.

Without a doubt, manufacturing is going to continue to evolve as technology continues to progress. CNC manufacturing and custom machined parts have already changed the way manufacturing functions. With computers able to perform multiple complicated tasks at the same time, consumer expectations have changed. It is important for manufacturers to stay ahead of the curve and meet these expectations.

Relying on High-Quality CNC Manufacturing

Precision manufacturing, such as CNC Machining, has completely changed the way that products are produced. It is important for manufacturers to rise to meet these changes so that they can remain competitive in the modern world. Having a high-quality CNC Machinist in a custom machine shop in Denver can help a company maintain an edge on their competitors. CNC machinery can help a business quickly produce high-quality results that will inspire loyalty among customers. To learn more about custom CNC precision machining in the Denver area, contact Tag Team Manufacturing today.