Anyone who uses machine tools to modify or make parts as a profession is a machinist. However, a person who has been properly trained to become a CNC machinist can do much more. A qualified machinist should be able to use CNC (Computer Numerical Control) to execute his/her duties. CNC refers to the process of using computers to control machines. It’s the automation of machine tools via machine control commands to execute pre-programmed sequences.

What Does a Machinist Do?

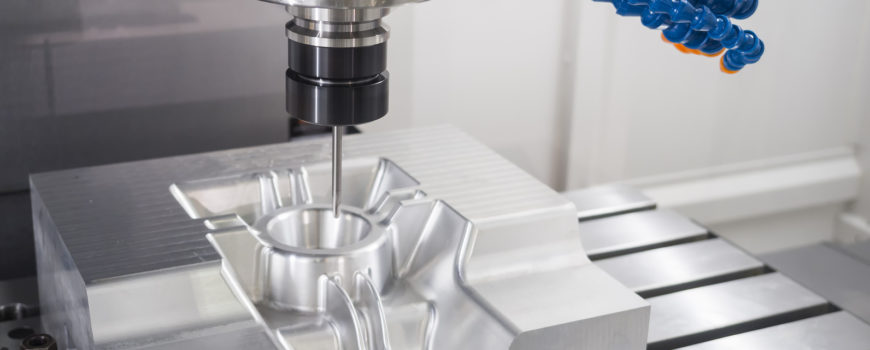

The terms CNC manufacturing, CNC automation, and CNC machining all allude to the use of Computer Numerical Control (CNC) via programming to increase quality and consistency of the product. A CNC machinist can operate a wide range of machinery in the creation of parts and products that are usually very specific. Machinists operate specialized tools to create precision metal parts. They repair, modify, and fabricate mechanical equipment.

A normal day in the life of a machinist includes:

– The use of manual and computer controlled machinery i.e. operate, set up, and program the CNC Machinery

– Making sure that the machinery is properly maintained.

– Operating tools such as grinders, milling machines, etc.

– Calculating where to bore or cut using the right tools for each job.

To become a CNC machinist, it’s good to complete a training program in one of the US manufacturing schools, or better still, one of the most reputable mechanical engineering schools in the land. Keep in mind that formal training is not a must – there a lot of self-taught machinists out there, but it’s strongly suggested that you acquire some form of formal training to effectively and safely discharge your duties. Courses like mechanical engineering include a pretty comprehensive machining training program. Many businesses with interests in manufacturing in the US do hire machinists.

Types of Machinists

Primarily, there are three types of CNC machinists. They are operating machinists, set up machinists, and programming machinists. An operation machinist is responsible for the day to day functioning of the machines – they are the operators. Set up machinists are tasked with the job of making sure that everything is in working order. They are in charge of monitoring the equipment, adjusting offsets, and performing other tasks needed to maintain smooth operations. Some machinists specialize in writing CNC programs and modify existing programs in response to glitches encountered during test runs. These machinists are known as programming machinists.

Becoming a Machinist

As stated earlier in the article, to become a professional CNC machinist, it’s prudent to acquire proper training and certification. If it’s possible, its best to start preparations to become a machinist early. In their training, machinists get several years of technical instruction and on-site training. Training can be acquired via community or technical colleges, vocational schools, and apprenticeship programs. Often, you will be required to have a high school diploma.

Typically, becoming a machinist takes between 1 to 2 years for entry level roles including a minimum of 8 weeks of technical training and over 1,500 hours of on the job training each year. Here’s what you need to do to become a machinist in the United States:

– Enrol for preparatory classes. A high school diploma is the minimum requirement to becoming a machinist. You can get the necessary training — in this case, a degree, usually taking up to two years — from a technical college

– Complete a formal apprenticeship. You can work with a local manufacturer, local union, or your school to look for available opportunities. An apprenticeship is an entry level position where you can stay for a year or two — depending on your training and tenacity — before moving up to an operator position.

– Get NIMS certification. A National Institute for Metalworking Skills (NIMS) certification isn’t a requirement, but its recommended for aspiring machinists. After completing your apprenticeship, get one of those. You will be required to sit for a performance-based written and practical exam to get certification.

The last and final step to becoming a machinist is putting your skills to work. You can do that by getting a job at a manufacturer specializing in making parts for OEMs (Original Equipment Manufacturers). Alternatively, you can choose to work for yourself if you have the business skills. Depending on your financial ability, you can either buy an existing Machine Shop or purchase a machine to handle some small jobs from your home or garage.