Quality control in manufacturing can be defined as the oversight of the different aspects of the manufacturing process. The main goal of implementing quality control in manufacturing is ensuring that products produced conform to the company’s, industry’s as well as consumer expectation every time. Having a system for quality control monitors everything including the parts being produced as well as the employees that are assembling the parts. It is not only the customer that benefits from quality control by receiving products of high quality, but also the manufacturer since it reduces costs and increases efficiency.

To effectively implement quality control programs, you have to approach with caution. Imperfect implementation can be costly to the company. Effective implementation starts by defining the quality standard of each product. Then define the number of products to be tested before proceeding to employee training. Finally, there should be a communication system to report defects or potential issues in cnc manufacturing.

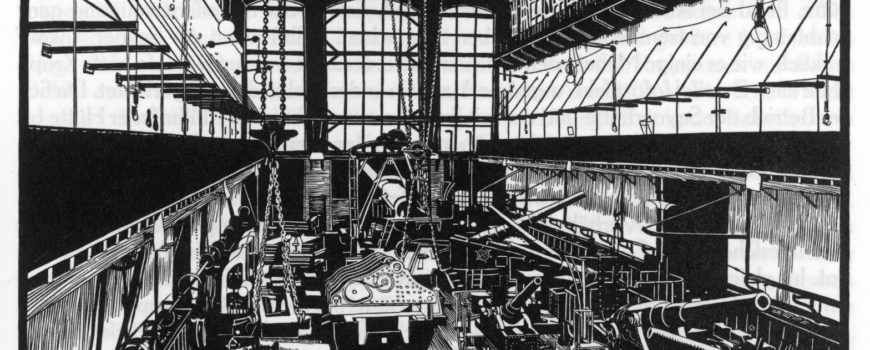

Below is an outline of the role of quality control in manufacturing in US.

Risk minimization

There is more to minimizing risks than having safety gear on the factory floor. There are plenty of other financial risks that should be considered not only in the factory but also after the product leaves the factory. Product recalls can be quite an expensive endeavor, they also influence the customer negatively hence tarnishing the name of your brand indefinitely. An effective quality control system that includes vigorous inspections at different stages of the manufacturing process helps ascertain that all manufactured products meet the minimum requirements before reaching the consumer.

Resource conservation

Resource conservation is important for manufacturers since it reduces the total upfront material expenses. It also helps improve the company’s reputation with its customers. With less assembly foul-ups there is greater throughput and higher gains for the manufacturer. The role played by quality control in resource conservation is making this a reality.

Effective compliance

Every industry has a set of regulations that it must meet including manufacture of cnc machining. Failure to comply with the standards set can be an expensive affair. It can also lead to production bottlenecks. A company with effective quality control systems will evenly distribute the checks throughout the entire process. Ensuring there are no financial losses resulting from bottlenecks in the manufacturing process.

Consistency

Consistency of the products produced and offered to the market plays a huge role in the overall company reputation. If you are not in a position to consistently produce high quality products, it will reflect badly on your company. Consistency not only affects your company reputation but it also affects production costs. If consistency is not upheld in manufacturing, you will definitely experience fluctuations in production costs. Quality control plays a huge role in ensuring you are consistent in the quality of products produced.

Improved final product

Naturally, products from a stringent and intensive the quality control environment are of higher quality. Quality control ensures that each step meets the standards that you have set. The results will be an improved product of high quality.

As evidenced above, quality control is an essential part in the manufacturing process. Not only does it ensure the company produces high quality products but also ensures that there is proper adherence to the standards set by the regulators.