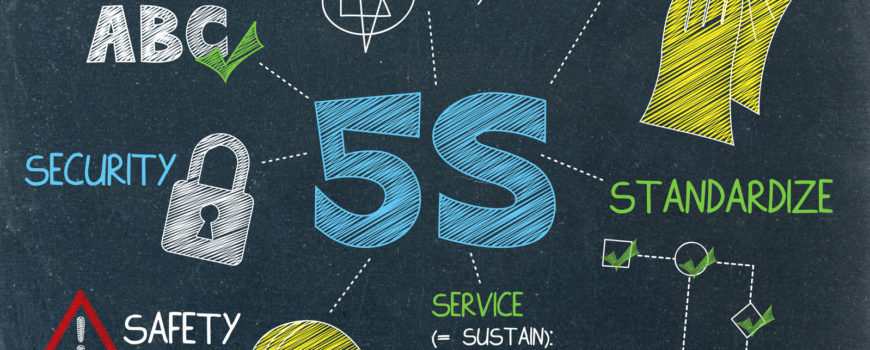

The efficiency and the safety of a manufacturing organization are vital for improved productivity, quality production, and profitability. The 5S is a methodology aimed at optimizing the productivity and reducing waste at the factory. It makes use of visual cues and an orderly workplace to achieve consistent results. The 5S is implemented by small teams working together to achieve a higher goal of efficiency. It can be performed in any company that does manufacturing in the USA.

Steps in 5S implementation

1. Sort

The first S deals with getting unwanted obstacles out of the way to enhance speed in the production activities. All unneeded items should be kept away and the right people allowed to do the job at hand. In essence, the production workplace should only have items needed for the current operations in their bare form.

Why is it important to sort?

With enough space, time and efforts can be managed effectively as everything is in its place. In addition, it removes any annoyances and hindrances in the workflow management and lowers incidences of injury where there are moving parts in the production process.

2. Set in Order

The setting order involves arranging items such that they are in the area that they would be used. Each item is labeled for the ease of identifying it at the workplace.

Why is it important?

Setting things in order eliminates several kinds of waste that include;

· Waste of human energy as workers look for items across the facility

· Downtime as production activities await the delivery of the said items

· Difficulty in inventory management as some of the items cannot be traced.

US manufacturing school also teach the importance of putting everything in order as it lowers the chances that a wrong raw material may be used in producing a particular item.

3. Shine

Keeping the workplaces clean enhances efficiency and work morale. Clean machines and tools also work efficiently and do not break down now and then. The workplace and tools used daily should be cleaned each end of the day so that everything is set for the next work day. This applies to hand tools and CNC machining equipment at the workplace.

Why is it important?

· Clean machines produce items with fewer defects

· Puddles of dirt and oil are more likely to cause slipping injuries

· If machines do not receive regular maintenance, they tend to break down more often

4. Standardize

The above-said procedures should be maintained each day. The management of the workplace should standardize the processes so that the conditions do not deteriorate at any point. Similarly, the quality of the products should be maintained by such technology as CNC automation. CNC manufacturing ensures mechanical engineering products are cut to precision every time and products are of the same quality all through.

5. Sustain

The improvements on the procedures should be efficient in the long term. Inspections and audits help determine the effectiveness of any improvement in the production environment. US manufacturing schools teach on quality control especially in mechanical engineering and other production industries. If any improvement does not improve the quality of the product, lower the cost of production or make the work easier, it is not worth implementing.

There is high competition among competing firms in US manufacturing industry. One way a company can lead the pack is by cutting down the waste and maintaining the product standards. In addition to the procedures taught in mechanical engineering schools production managers should enhance optimal productivity by making the workplace efficient, clean and inviting.