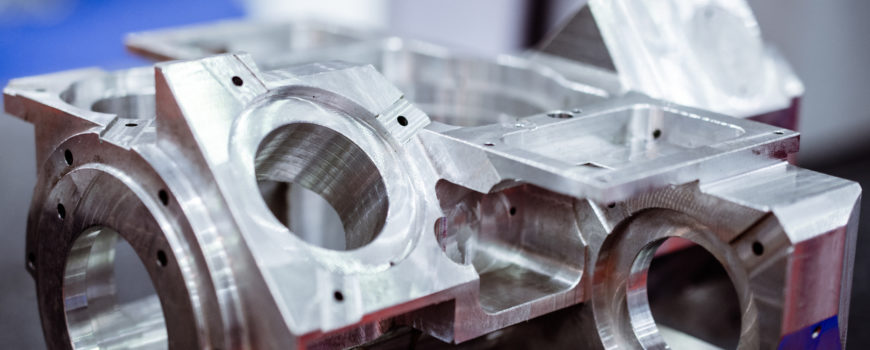

The best practices for precision manufacturing come from using computer numerical controlled (CNC) machining. CNC manufacturing uses high-speed, robot-driven machines and specialized cutting equipment in a custom machine shop. A machine shop for CNC manufacturing will have vertical and horizontal milling machines and lathes.

This CNC process can make custom machined parts to meet the exact specifications of the original equipment manufacturer (OEM) parts. Besides precision manufacturing, a CNC machinist can perform prototype machining in preparation for full-run CNC manufacturing.

This is a guide to the best practices with practical tips on how to create designs, use prototype machining, and choose materials that result in the most cost-efficient custom machined parts produced by CNC machining.

It Starts With Superb Design

Before the machine shop work can begin, creating a precise computer-aided design (CAD) model is the first step. Then, the CAD model is loaded into computer-aided manufacturing (CAM) software. This creates the instructions that tell the robotic machines how to move in order to cut away material from a manufacturing blank in order to form the desired end result.

The instructions are very detailed and include the following:

· The tool paths that are necessary, based on the geometry of the finished part.

· How fast the cutting machine should move.

· How fast and in what direction to turn the materials stock and/or the cutting tool.

· The precise locations and how to move, based on a three- or five-axis coordinate system.

The computer controls of the machine doing the cutting work guide the movements on all three X, Y, and Z axis simultaneously, making complex cuts and detailed geometric patterns possible.

Choosing the Right Cutting Tool for the Design

A CNC lathe has a fixed cutting tool and the material stock rotates. A CNC mill is the opposite, With a mill, the tool rotates and the material stock is stationary. Using a CNC lathe produces a better result for complex cylindrical shapes.

If a part requires square features, these are better made using a CNC mill. If a round part has a square feature, then first the round geometry is produced on a CNC lathe and then the square features are cut with a CNC mill.

Part sizes are limited to the tool clearance of milling machines and the depth of the cuts possible. Lathe part size capability depends on the build space. A live tooling lathe combines CNC milling capability within the lathe, which is a beneficial tooling solution to increase the features that can be produced and reduce lead times.

Default Tolerances

Unless a customer provides specifications that include tolerances, the general permissible tolerance levels are plus or minus 0.005 inches for metal parts and plus or minus 0.010 inches for plastic parts. The walls of metal parts are a minimum of 0.030 inches thick. The walls of plastic parts are a minimum of 0.060 inches thick.

The best practice is to mill the finish to a maximum 125 micro-inches as measured by the root-mean-square (RMS) of the peaks and the valleys of the surface. Surface finish treatment is only applied if requested.

Tighter Tolerances

Very tight tolerances are possible that exceed the standard default tolerances. However, tighter tolerances result in added expense because a tighter tolerance may increase waste, require more fixturing, and/or additional measurement processes. Longer cycle times may be necessary to slow down the machining in order to achieve tighter tolerances. Therefore, tighter tolerances should only be specified when necessary to achieve critical design specifications.

Material Choices and Blank Size

Raw material selection is determined based on the part’s design, functionality, and cost limitations. There is usually a need for certain material characteristics such as chemical resistance, rigidity, thermal stability, heat treat-ability, hardness, and others.

The type of raw material used strongly influences the cost of the part. Plastics are preferred and are much less expensive. Plastics are a wise choice if the rigidity of metal is not needed. Metals that are softer, such as brass and aluminum, are easier to machine than stainless steel and carbon steel.

As a general rule, add 0.125 inches to the material size in all three directions of width, length, and depth. This is the necessary size of the material blank to be used for cutting. It is more cost effective to used standard material blanks if possible. For example, if a part can have the dimensions of 0.875 inches or less on each side, then a standard one-inch cube as the material blank can be used.

Part Complexity — Three-Axis vs. Five-Axis Machining

Two-axis cuts are the easiest and least costly. For a more contoured part, three-axis cutting is necessary with the cuts being made by the tool or blank moving simultaneously on the X., Y, and Z axis.

With five-axis machining more complex parts can be made in a cost-efficient way. In five-axis cutting, the tool and the blank move simultaneously around in five ways. Five-axis machining reduces the number of setups needed, achieves faster cutting speeds, uses better tool paths, and results in a better surface finish.

Fillets

A CNC milling machine (horizontal or vertical) makes interior vertical walls with a radius. It is a round tool, which spins at a high revolution per minute (RPM) that removes the blank material. This limits designs to allow for where radii occur.

Inside corner fillets are easier to make by using a radius that is non-standard. End mills need clearance to turn and to continue milling. By adding 0.02 inches to an internal radius, the cutter can turn slightly without having to stop. This reduces cost and results in better CNC parts. In general, the larger the radius the lower the cost.

Floor fillets are easier to machine if the floor radius is less than the corner radius. If the floor and wall radius is the same size, then it makes it challenging to remove the corner material. If the floor radius is somewhat smaller than the wall radius, then the same tool can be used to create a nice flow through the corner.

Undercuts

If a standard machining tool cannot reach an area, this creates an undercut region on a part. It is better to avoid the need for a special tool that would be required if the feature is not a standard dimension because a custom tool is expensive. A standard tool is less than half the cost of a custom tool. It is also important to make sure the undercut can be reached and is not too deep. A less shallow undercut is better.

Threads

To reduce costs, use standard thread sizes and the largest thread size possible. Small taps have a greater chance of breaking during production than larger ones do. Only specify the depth of the tap necessary because deep, threaded holes increase the cost of the part. A custom tool may be needed for very deep holes.

Surface Finishes

The standard milled finish is 125 RMS. With this finish, minor tools marks may be visible. Smoother finishes of 63 RMS, 32 RMS, or 16 RMS are possible, but they increase the processing time necessary to make the part.

A bead-blast finish creates a matte surface by blowing tiny glass beads under pressure at the surface. If the masking of some areas from the bead blasting is necessary, this adds to the expense.

A corrosion-resistant finish can be created by anodizing a metal part. This can be done with a transparent finish or in different colors (red, black, gold, etc.). This is a popular finish for aluminum parts. Hard-anodizing is also available that creates a thicker, wear-resistant surface layer.

A powder-coat paint finish is created by spraying on paint and then baking the painted part in an oven. This creates a very strong finish that is wear- and corrosion-resistant. It is more durable than regular paint. Many colors are available to create a nicely-finished look for a part.

Custom finishes are also available, at additional expense, such as plating or specialized chemical films.

Summary

By following these best practices as a guide, it is possible to get excellent results when working with Tag Team Manufacturing. This is a machine shop Denver has that can produce up to 50,000 components annually for Denver manufacturing and other locations. Contact Tag Team Manufacturing for a quote from the best Denver CNC machine shop.