Considering the current scolding regarding the importance of the US manufacturing industry, there have been critics who have tried to discredit the benefits associated with manufacturing in the current transformational age. However, their arguments are not right considering these seven benefits associated with US manufacturing.

Manufacturing enables Creation of Strong Middle-class Jobs.

Regardless of the claims from critics that manufacturing jobs are unpleasant, they, in fact, have not been to a modern machine shop as these offer a good work environment and a dependable source of income for many American families. Furthermore, most of them come with irresistible perks such as good health insurance, 401k plans and short term disability for its employees. Also, despite the fact that all jobs are good depending on personal preferences, some higher positions even pay up to $80,000-$100,000+ per year!

Manufacturing Creates Jobs

With a relatively high unemployment rate particularly among the youth, expansion of the US manufacturing industry has gone a long way in providing the much-needed jobs. Now, trade schools offer a 2-4 year education in Precision Machining. This is a good starting point if you are interested in manufacturing and machining. Unlike other positions that require high qualifications, entry level manufacturing jobs do not require such specialized skills and can absorb anyone willing to learn (although some schooling is a plus and will help the employee move up in the company). With schooling and on the job training, anyone with a passion in manufacturing can fit into the industry.

Manufacturing creates National Wealth

Buying and consuming imported goods will only make the country poorer since there will be no foreign income. However, by manufacturing products which can be sold locally and internationally, the nation’s economy becomes stronger since there will be foreign cash.

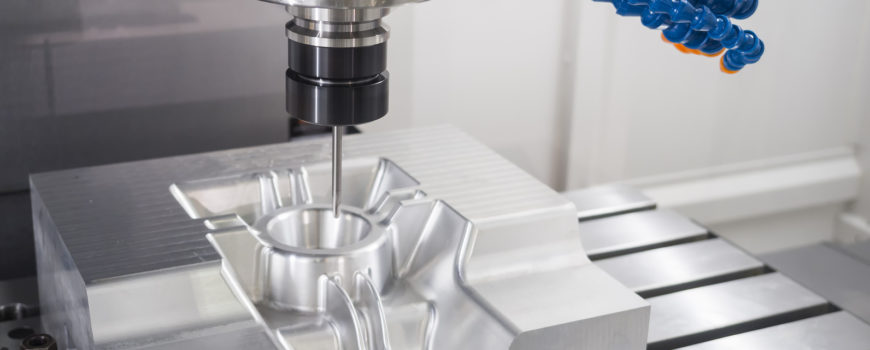

Factories/ Machine Shops are now Safer than before

The current American factories are very safe now and those interested in the industry should not be worried to work in this type of setting. Rarely are their incidences of safety breach or accidents with proper training and shop safety. Also, with the recent embracement of the worker safety policy countrywide, the possible safety incidences are continually being suppressed.

U.S. Industries are very clean

Compared to other countries where waste products are directed in rivers and other water bodies, American factories a very clean and are even getting cleaner. The waste produced in US manufacturing industries is treated and recycled to ensure that it does not harm the environment. As such, the world will be a healthier place if people bought more goods from the U.S. compared to other countries.

Workers with good jobs are healthy

Jobs in the US manufacturing industry are in most cases physically taxing. Whereas this may be seen as a negative, it is, in fact, good for the employee’s health as working in manufacturing also doubles up as exercise. Machinists are on their feet all day, constantly moving around. As a result, earning money and remaining healthy go hand in hand.

Manufacturing research leads to creative ideas

The US manufacturing industry contributes to approximately 75% of the private sector development and research. The mind-blowing innovations from the U.S. manufacturers keep the country competitive in the global platform hence making it an economic powerhouse.

In a nutshell, if taken alone, the manufacturing industry is the ninth largest economy in the world. As such, critics need to reevaluate their stand about the U.S. manufacturing industry.